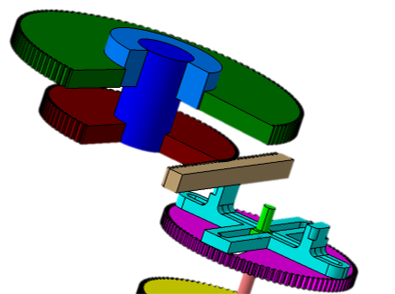

Crankpin Displacement Mechanism

Salient features of the IVT:

- Non-friction dependent (all geared). No slip.

- Does not require additional electric motor or hydraulic pump/motor for operation.

- Uniform and steady output for a steady input

- Co-axial input / output

- Ranging from full forward to full reverse

- High torque capability

- Efficient, Versatile and Scalable

- Simple construction and assembly

- Compact and Light weight

- Cheaper to manufacture

- Use of readily available commercial off the shelf (COTS) components

- Eliminates the need for clutch

- Possibly eliminates the need for a torque converter

- Multiple configurations aid packaging within available space

- Eco-friendly (increased fuel efficiency)

- Can easily replace/retrofit existing regular transmissions with minor changes

Shortcomings of other CVT/IVT in the market

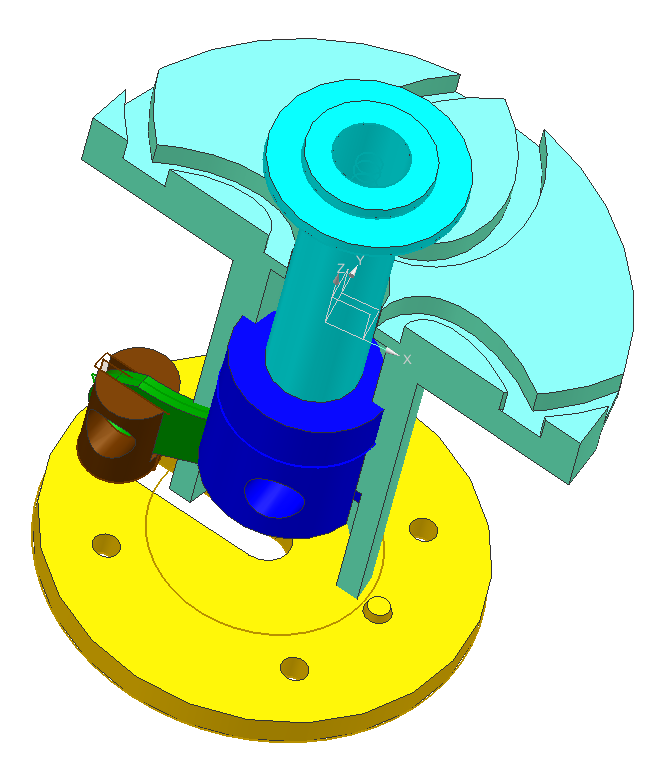

Scalability and Versatility

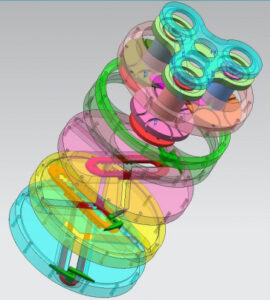

Custom Geneva Pin and Slot Mechanism for Controlled Rotation

- Use of custom Geneva mechanism in transmissions (patent pending)

- Used to achieve constant rack velocity of a scotch yoke mechanism and thereby achieving constant angular velocity of the pinion

Custom Geneva Mechanism (6 modules)

Patented technology in US, Japan and China and patent penting in multiple other countries on multiple innovative designs for Infinitely Variable Transmission (IVT) that is NON-DEPENDENT ON FRICTION AND PROVIDES UNIFORM INPUT TO OUTPUT RATIO. We have built a hand-held prototype for proof of concept/product demonstration. We are currently working on building a prototype for a tractor

decelerates to a stop, and then repeats in the reverse direction